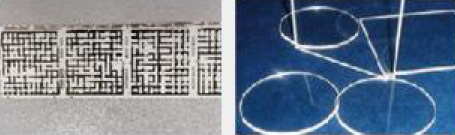

High precision cutting blades for semiconductor industry

| Blade type | Blade cutting application field | |

| Electroformed hard dicing blade | Semiconductor wafers and other silicon materials |  |

| Electroformed soft dicing blade | LED packaging materials, piezoelectric ceramics and other materials |  |

| Metal Blade | Integrated circuit packaging materials, ceramic materials, etc |  |

| Resin Blade | Integrated circuit packaging materials, superhard materials such as glass, etc |  |

Application of UV cutting tape

A

Application areas of A-series products

- PCB substrate

- (BGA/QFN)

- Glass

B

Application areas of B-series products

- wafer

- MEMS

- Glass

C

Application areas of C-series products

- Ceramic

- Glass

- Crystal

V

Application areas of V series products

- wafer sawing

- Inverted film

- Expandable membrane

N

Application areas of N series products

- Non UV products

- Blue film, etc

UV film product application

PACKAGE cutting

Product model: A15010-12C、A15010-32、A15020-12C

Application process: Traditional packaging QFN, DFN, BGA and other packaging after slicing

Processing material: Epoxy resin (minimum chip size 0.6 * 0.3MM)

| Model | Base Material | Total Thickness | 180 ° Adhesion (After UV) |

| A15010-32 | PO(150μm) | 160 | 9.78(0.04) |

| A15010-12C | PO(150μm) | 160 | 15.6(0.04) |

| A15015-62H | PO(150μm) | 165 | 18.6(0.04) |

| A15020-12C | PO(150μm) | 170 | 20.3(0.05) |

MEMS product slicing

Product model: A15020-12C、A15010-12C

Application process: Wafer cutting after MEMS packaging

Processing material: epoxy resin

| Model | Base Material | Total Thickness | 180 ° adhesion (after UV) |

| A15010-12C | PO(150μm) | 170 | 15.6(0.04) |

| A15020-12C | PO(150μm) | 160 | 20.3(0.05) |

LED product slicing

Product model: A15020-32A A15010-32

Application process: After SMD and CSP packaging, chip cutting or cutting separation is required

Processing materials: EMC substrate, organic silicon, etc

| Model | Base Material | Total Thickness | 180 ° adhesion (after UV) |

| A15010-32 | PO(150μm) | 160 | 9.78(0.04) |

| A15020-12C | PO(150μm) | 170 | 18.7(0.05) |

WAFER marking

Product model: V07010-12M B09010-22D B08005-22

Application process: wafer slicing

Processing materials: WAFER

| Model | Base Material | Total Thickness | 180 ° adhesion (after UV) |

| V07010-12M | PO(150μm) | 80 | 3.52(0.04) |

| B09010--22D | PO(90μm) | 100 | 4.93(0.04) |

| B08005-22 | PO(80μm) | 85 | 7.73(0.06) |

WAFER marking

Product model: B09010-2E2A

Application process: wafer slicing

Processing materials: WAFER

| Model | Base Material | Total Thickness | 180 ° adhesion (after UV) | Anti Static |

| B09010--2E2A | PO(90μm) | 100 | 8.083(0.06) | The anti-static effect of the adhesive surface reaches 109 |