Wafer level high-precision

cutting blades

01

The DZY wafer dicing blade is mainly used for high-precision cutting of wafers to meet the high requirements for cutting accuracy and efficiency in semiconductor packaging processes.

More +02

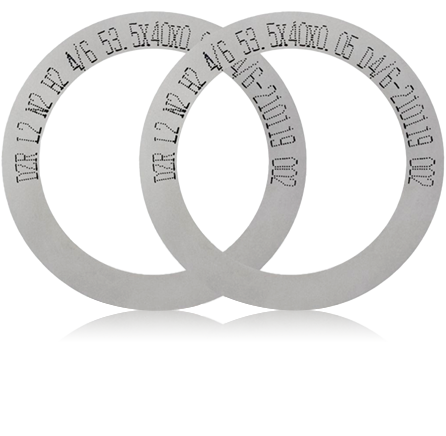

DZR cutting blades are widely used in industries such as semiconductors, optical communications, and new functional materials, providing efficient and stable cutting solutions for these industries.

More +03

DZR-S Series Slotted dicing blade

The DZR-S slotted blade has a wide range of applications in semiconductor wafer cutting, functional ceramic cutting, alloy material cutting, and semiconductor packaging component cutting.

More +04

During the cutting process, the metal dicing blade is driven by the spindle to rotate at high speed, utilizing the sharpness and hardness of the blade to remove metal materials.

More +05

Resin dicing blade is a high-performance, high-precision professional cutting tool with a wide range of applications and significant performance advantages.

More +06

UV adhesive tape is a special type of tape that has strong adhesion under normal conditions, but its adhesion decreases sharply after exposure to ultraviolet (UV) light.

More +WINTIME Semiconductor

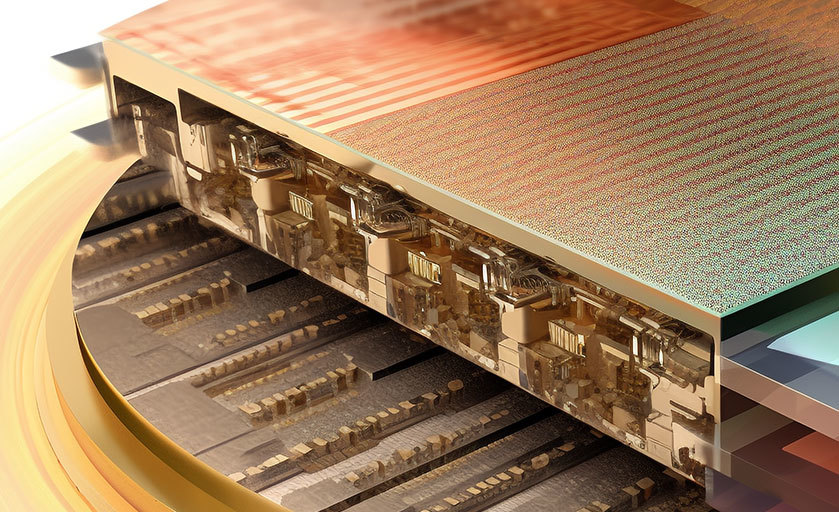

WINTIME Semiconductor was founded in 2020 and is a high-tech enterprise that integrates the research and development, production, and sales of wafer level high-precision cutting blades. We provide customers with high-precision cutting solutions throughout the entire process, helping to improve cutting quality and reduce production costs. We are a recognized supplier of high-precision cutting blades, cutting tapes, and cutting solutions by many leading domestic and foreign enterprises. In 2023, the total investment of Nantong WINTIME Semiconductor Special Materials Project was nearly tens of millions of yuan, with a newly built factory and ancillary buildings of 34000 square meters. The annual production capacity of the cutting blade exceeded 1 million pieces, ranking among the top in the country. It has 29 patented technologies and has achieved excellent results in national, provincial, and municipal science and technology competitions and entrepreneurship competitions. The company has completed the "ultra-thin wafer slicing knife" project, which achieves ultra-thin thickness of less than 9 microns in terms of technology, and the product quality has reached the international forefront level. It is currently one of the few domestic enterprises that can achieve mass production. As a domestically developed project, we aim to localize high-end industries while ensuring advanced technology.

The company was established in

Plant area

have patented technology

WINTIME our strength

Technical process

Ultra-thin blade thickness within 9 microns

The annual production capacity of dicing blade exceeds 1 million pieces, ranking first in the country. The company has developed and completed the "ultra-thin wafer dicing dicing blade" project, which has achieved an ultra-thin thickness of less than 9 microns in technology, and the product quality has reached the international cutting-edge level. It is currently one of the few domestic enterprises that can achieve mass production.

Ultra-thin thickness up to 9 microns

Annual production of dicing blade

Learn about the latest Weiteng

Information dynamics

On December 3rd, Nantong Wintime Semiconductor Technology Co., Ltd. gladly attended the award ceremony for the "2024 Yangtze River Delta Industrial Innovation Belt Entrepreneurship Talent Invitation Competition"

2024-12-04

The 6th "China Innovation and Entrepreneurship Competition"

From September 24 to September 26, the highly anticipated 6th "China Innovation and Entrepreneurship Competition" grandly opened in the historic city of Datong

2024-09-27